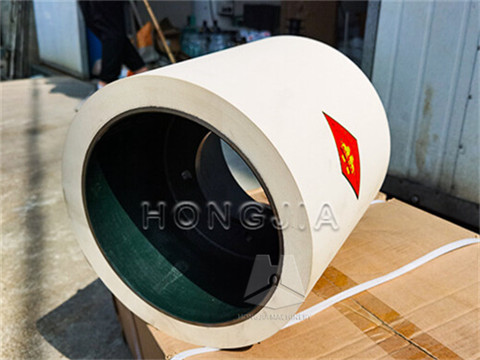

Rice Rubber Roller

Rice Rubber Roller is used in the rice mill process for separating husk from rice. We are among the top rice rubber roller manufacturer in China. We are making all types of paddy dehusking rubber roll for rice husker.

Rice Rubber Roller is used in the rice mill process for separating husk from rice. We are among the top rice rubber roller manufacturer in China. We are making all types of paddy dehusking rubber roll for rice husker.

Rice Rubber Rollers for Rice Huller Introduction

Rice Rubber Roller is used in the rice mill process for separating husk from rice. We are among the top rice rubber roller manufacturer in China. We are making all types of paddy dehusking rubber rolls for rice huskers. The rice rubber roll for the rice mill come in many different sizes. Our company makes all types of dehusking rice rubber rolls since rice huller rubber roller base is very important. At the same time, the rice rubber roller is also a vulnerable part of the rice milling process. It is recommended to purchase more matching rubber rollers as spare parts when purchasing the rice mill plant.

Rice Rubber Roller Specifications

Rice hulling roll is one of the most important and required equipment in the hauling industry. And plays an important role in the rice manufacturing industries.

In a rice mill huller roller, there are two rollers of the same diameter attached. However, they operate at different speeds. The position of one of the rollers is fixed. Moreover, the other roller’s position is changed depending on the desired clearance.

The roller adjusted (for each milling cycle) has to run slower in comparison to the fixed roller operated at a higher speed. There is an aspirator attached at the base of the machine to separate the hulls from the brown rice.

Before indulging in any of the rubber rolls for the rice mill for all your needs, We need to know our rice mill rubber roller’s specifications

Durability

The rice rubber roller should be constructed of a durable material that can be selected for its oil and resistance properties. This gives a better yield and output of the material processed. A compounded rubber material provides

Rubber Roller Technical Data

Tensile strength: Mpa/2mm 25.2-26 (standard level: Mpa≥19)

Wear reduction cm³/1.61km: 0.02-0.05 (standard level:≤0.5)

Break elongation: 320-360% (standard level:≥200)

Shore A Hardness: 90°~97(standard level:85°~90°~95°)

Material: NBR

Our Rice Rubber Roller Character

1. Optimum efficiency for longer and smoother service life, and better output.

2. Better heat resistance and better abrasion-resistant properties.

3. Maximum hulling rate with the lowest breakage.

4. Non-poisonous and environmental protection

Cautions !!

1. Carefully handled during the transportation.

2. During the fitting, one pair of rollers must be fitted at the same level, and the interval must be equal.

3. Store in a dry place, away from Acid, Alkali, Salt, oil, and dirty, avoid insolation

4. Keep paddy cleaning when the rice mill working

Rubber Roller Technical Data Specifications

| Model(Inch) | Outer Diameter(MM) | Length(MM) |

| 4″ | 182 | 100 |

| 6″ | 222 | 152 |

| 8″ | 255 | 200 |

| 10″ | 255 | 254 |

| 12″ | 268 | 300 |

| 14″ | 227 | 355 |

| 20″ | 255 | 508 |