Rice Emery Roller and Its Effect on Rice Quality

The effect of rice grinding rollers on the quality of rice

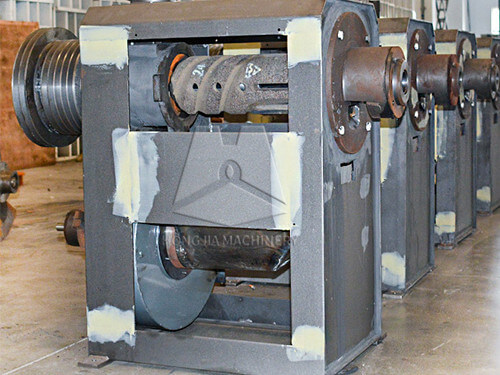

The rice mill machine uses rotating rollers to make the rice grains and the whitening chamber components and the rice grains and rice grains collide with each other, rub and roll and other movements, and partially or entirely remove the skin of the rice grains through grinding friction and rubbing away. The process of becoming rice that meets predetermined quality requirements.

According to the different roller materials, rice mills can be roughly divided into sand and iron roller rice mills. Compared with the iron roller rice mill, the sand roller rice mill has the advantages of soft collision and tumbling, low broken rice rate, low power consumption, high rice yield, and high production efficiency, so it is the most widely used in rice processing enterprises at present.

The rice grinding roller is a key wearing part that is replaced frequently in the grinding roller rice mill, and within a certain range, its quality also seriously affects the rice mill's output, yield, power consumption, and broken rice rate.

Rice milling process performance of rice milling roller and its influence on rice quality

1. Granularity

The particle size of the rice grinding roller refers to the particle size of the abrasive that constitutes the rice grinding roller. Particle size refers to the size of abrasive particles.

2. Hardness

The hardness of the rice-grinding sand roller indicates the firmness of the bonding of the abrasive particles, which refers to the difficulty of the abrasives falling off under the action of the external force of the rice-grinding sand roller. If the abrasive particles easily fall off, it indicates that the hardness of the rice grinding roller is low.

3. Organization number

The organization number of the rice-grinding sand roll indicates the volume occupancy of the abrasive grains in the rice-grinding sand roll, that is, the abrasive grain rate.

In the rice grinding roller, the abrasive grains should be evenly distributed, and the organizational structure should be uniform. The organization number of the rice grinding roller reflects the looseness of the rice grinding roller and the number of abrasive particles involved in the grinding action per unit area.

The small organization number indicates that the abrasive grain content of the rice milling sand roller is high, the rice milling efficiency is high, and the rice milling sand roller has low abrasion and long service life.

4. Strength

The strength of the rice grinding roller refers to the ability of the rice grinding roller to resist crushing due to the centrifugal force in the high-speed rotation. In order to ensure that the rice grinding roller will not be broken during normal operation, the working speed of the rice grinding roller should be limited to a certain extent.

Practice shows that the safe working line speed of the rice grinding roller should not exceed 20m/s. There are many factors that affect the strength of the rice-grinding roller. In addition to the strict compliance with the operating procedures during transportation, storage, storage, installation, disassembly, and use of the rice-grinding roller, the factors of the rice-grinding roller itself also have a great impact on the strength.

If other conditions remain unchanged, usually the greater the physical and mechanical strength of the binder, the thicker the wall thickness (radial dimension) of the rice milling roller, the higher the dimensional accuracy of the geometric shape and position, and the static and dynamic unbalance. The smaller it is, the higher the strength of the rice grinding roller.

If the strength of the rice machine sand roller is too low, the organization structure of the rice milling sand roller is loose, and the rice milling sand roller easily falls off in pieces during operation, which is a phenomenon often encountered in actual production.

Its structure not only reduces the service life of the rice grinding roller but also easily damages the rice grains, resulting in broken rice; in addition, the abrasive particles mixed in the finished product also affect the process performance of the subsequent process and the quality grade and price of the rice.

Therefore, efforts should be made to improve the strength of the rice grinding roller and prolong the service life of the rice grinding roller to improve the quality of the rice.

Rice grinding rollers and their impact on rice quality are the common concerns of rice processing enterprises and grain processing scientists.

We believe that according to the quality of raw grains and the quality requirements of rice processing, efforts should be made to improve the uniformity of structure, physical and mechanical strength, and geometric shape position of rice grinding rollers by optimizing the formula, roll shape design and manufacturing process of rice grinding rollers.

Dimensional accuracy, reducing defects such as lumps falling off and dynamic unbalance of the rice milling roller. Do a good job in the storage, storage, and assembly of the rice grinding rollers, pay attention to and strengthen the ventilation and bran discharge in the whitening room, so as to cool the rice grains, reduce the temperature of the rice, reduce the power consumption, reduce the broken rice, and improve the effect of the rice milling process.

In order to ensure that rice processing and production enterprises obtain good social and economic benefits, and prolong the service life of rice grinding rollers.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plant, rice processing plants, and paddy parboiling plant, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111